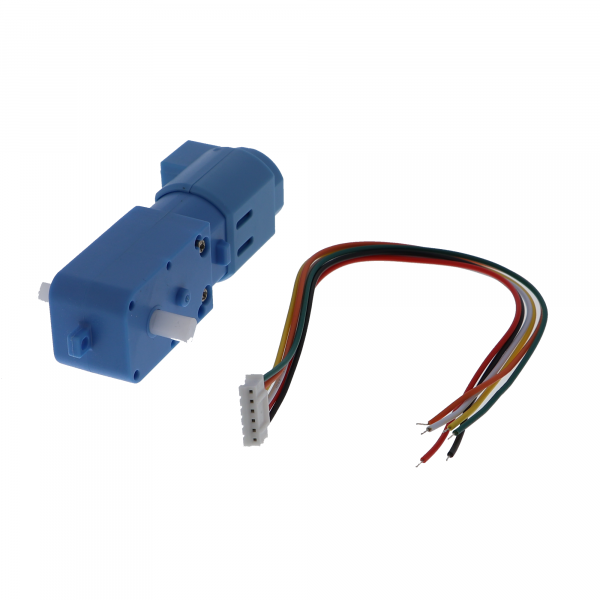

TT geared motor with Hall encoder (AB) & double shaft - 300 rpm

incl. VAT plus shipping costs

Ready to ship immediately

1-3 business days

We are known for

- Fast shipping across Germany

- 100,000+ satisfied customers

- Over 10 years of experience

- Item no: F23105692

- Weight: 0,04 kg

- Packing dimensions: 8 cm x 2.2 cm x 2.5 cm (L x W x H)

This TT DC geared motor with double shaft and integrated Hall encoder (2 channels) is ideal for precise speed measurement and direction/displacement detection in robotics and DIY projects (e.g. Arduino / Raspberry Pi, smart car, STEM). The encoder provides two phase-shifted square wave signals (H1/H2), which means that the direction of rotation can be reliably determined in addition to the speed.

Technical details

Pin assignment / connections

Encoder (Hall):

-

G = Hall supply GND

-

V = Hall supply + (typically 3.3 V or 5 V, depending on the microcontroller)

-

H1 = Hall output channel 1 (square wave)

-

H2 = Hall output channel 2 (square wave)

Motor:

-

M+ = motor supply plus

-

M- = Motor supply minus

Important:

-

The voltage V-G (encoder) depends on your controller (typically 3.3 V / 5 V).

-

The voltage M+-M- is the motor voltage (6 V or 12 V depending on the variant).

-

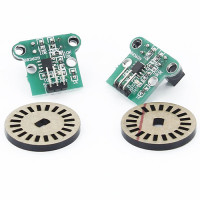

There is a magnetic disk on the shaft (N-/S-pole ranges).

-

The Hall sensor recognizes the poles and generates a square wave from them: e.g. high at S pole, low at N pole.

-

H1 and H2 are arranged at different positions → the signals are out of phase (quadrature).

This allows you to: -

Calculate thespeed from the frequency/period duration

-

Determinethe direction of rotation via the phase position H1 vs. H2

Speed calculation (from period duration)

If the magnetic disk P generates poles (or pole segments) and the measured period duration of the Hall square wave T is: n=60/P⋅T

-

n in rpm

-

T in seconds

-

P = number of magnetic poles/segments (depending on the magnetic disk used)

Dimensions

-

Total length: ~ 79.95 mm

-

Gearbox housing width: ~ 22.40 mm

-

Motor/housing height: ~ 25.79 mm

-

Output shaft: Ø ~ 5.40 mm

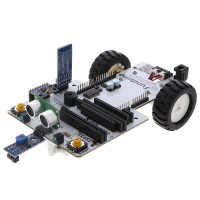

Typical applications

-

Encoder wheel / odometry (displacement measurement)

-

Robot chassis, smart car, line follower

-

Speed control (PID), RPM measurement

-

Teaching/STEM projects, prototyping

Scope of delivery

- 1x TT geared motor with Hall encoder (AB) & double shaft - 300 rpm, incl. connection cable

This TT DC geared motor with double shaft and integrated Hall encoder (2 channels) is ideal for precise speed measurement and direction/displacement detection in robotics and DIY projects (e.g. Arduino / Raspberry Pi, smart car, STEM). The encoder provides two phase-shifted square wave signals (H1/H2), which means that the direction of rotation can be reliably determined in addition to the speed.

Technical details

Pin assignment / connections

Encoder (Hall):

-

G = Hall supply GND

-

V = Hall supply + (typically 3.3 V or 5 V, depending on the microcontroller)

-

H1 = Hall output channel 1 (square wave)

-

H2 = Hall output channel 2 (square wave)

Motor:

-

M+ = motor supply plus

-

M- = Motor supply minus

Important:

-

The voltage V-G (encoder) depends on your controller (typically 3.3 V / 5 V).

-

The voltage M+-M- is the motor voltage (6 V or 12 V depending on the variant).

-

There is a magnetic disk on the shaft (N-/S-pole ranges).

-

The Hall sensor recognizes the poles and generates a square wave from them: e.g. high at S pole, low at N pole.

-

H1 and H2 are arranged at different positions → the signals are out of phase (quadrature).

This allows you to: -

Calculate thespeed from the frequency/period duration

-

Determinethe direction of rotation via the phase position H1 vs. H2

Speed calculation (from period duration)

If the magnetic disk P generates poles (or pole segments) and the measured period duration of the Hall square wave T is: n=60/P⋅T

-

n in rpm

-

T in seconds

-

P = number of magnetic poles/segments (depending on the magnetic disk used)

Dimensions

-

Total length: ~ 79.95 mm

-

Gearbox housing width: ~ 22.40 mm

-

Motor/housing height: ~ 25.79 mm

-

Output shaft: Ø ~ 5.40 mm

Typical applications

-

Encoder wheel / odometry (displacement measurement)

-

Robot chassis, smart car, line follower

-

Speed control (PID), RPM measurement

-

Teaching/STEM projects, prototyping

Scope of delivery

- 1x TT geared motor with Hall encoder (AB) & double shaft - 300 rpm, incl. connection cable