Hole pattern PCB: Basis for prototyping

Perforated circuit boards, often colloquially referred to as printed circuit boards, are conductive circuit boards. The breadboards are used as base carriers for electronic components. They are equipped with a large number of mounting holes with a predefined hole grid spacing of 2.54mm and are therefore compatible with many components within microelectronics. Components are permanently mounted on these mounting points using soldering tools or screws.

The core of the breadboards often consists of an insulated material such as plastic or paper. To increase the conductivity of the non-conductive material, it is coated with a thin layer of copper.

Application of breadboards in microelectronics

In contrast to the conventional breadboard, in which components can be inserted and removed in seconds, electronic components are permanently mounted on a printed circuit board. The advantage of circuits mounted on a printed circuit board is their longevity. Among other things, the permanent mounting of the components provides protection against detached contacts in an environment in which the prototype is exposed to vibrations, for example. Printed circuit boards are therefore mainly used when a previously tested circuit is to be tested under difficult conditions over a longer period of time.

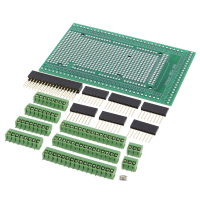

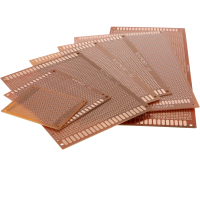

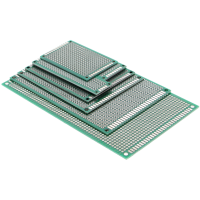

In our online store you will find breadboards in different sizes, shapes and insulated materials. If you have any questions, please do not hesitate to contact us.