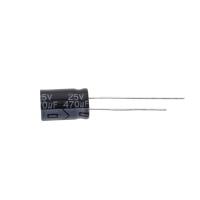

Buy electrolytic capacitor for microelectronics

Electrolytic capacitors, known as electrolytic capacitors for short, perform a special function in a circuit because they serve as capacitive intermediate storage devices. Elkos are used to decouple unwanted frequencies and smooth out voltages within a circuit. The electrolytic capacitors also serve as energy storage in DC circuits and buffer load peaks caused by the supply voltages.

Within the capacitor assembly, electrolytic capacitors have a capacitance that is comparatively high in direct comparison with ceramic capacitors or film capacitors.

Important note: Elkos may only be operated with DC voltage, because incorrect polarity (the anode is the positive pole) could explosively destroy the electrolytic capacitor.

Trimmer capacitors - variably adjustable capacitors

Trimmer capacitors (tricos) belong to the group of variable capacitors and serve as capacitive energy storage devices.

Unlike film, ceramic and electrolytic capacitors, tricos are used only for fine initial calibration of electronic devices during manufacture and maintenance. During initial commissioning or repair of a device, they are used to balance electrical oscillating circuits.

Ceramic capacitors in microelectronics

Ceramic capacitors (Kerkos), along with film and electrolytic capacitors, also belong to the group of electrical capacitors. They consist of a thin ceramic layer that acts as a dielectric, i.e. an insulating layer, within the component. This ceramic layer gives the capacitor its name.

Ceramic capacitors are divided into two classes:

Class 1 capacitors are used within electrical circuits with high frequency accuracy.

Class 2 capacitors are used in circuits where particularly high capacitance values are required. They are characterized by particularly high volume efficiency.

The film capacitor - what is it?

Film capacitors (Folkos), along with ceramic capacitors and electrolytic capacitors, are among the most commonly used capacitor designs. They also serve as capacitive energy storage devices.

The special feature of film capacitors is their design: in order to achieve a particularly high capacitance, an ideally extremely thin, tear-resistant and temperature-resistant film is used for this type of capacitor. During manufacture, a dielectric (i.e. an electrically weak or non-conductive substance) is wound between two of these foils, which are usually made of aluminum

Film capacitors are characterized by a comparatively small tolerance, a very long service life and high reliability.

The design of film capacitors can be roughly divided into two groups. We distinguish between an oval and a rectangular shape. In both designs sealed with epoxy.